Understanding Gas Plumbing: A Quick Guide

Understanding gas plumbing can be a daunting task, but it doesn’t have to be. It’s estimated that almost 80% of all households in the US rely on natural gas for heating and other services, so having an understanding of how this system works is essential.

In this article, we’ll cover everything from the basics – such as safety precautions and types of materials used – to more advanced topics like installation tips and troubleshooting common issues. We’ll also look at some best practices when it comes to maintaining your gas plumbing system and how to properly identify any potential problems.

By the end of this guide, you should have a better idea of how these systems work and be able to make educated decisions about their upkeep.

Safety Precautions

When it comes to gas plumbing, safety is always the number one priority. That’s why I’m here to give you all a quick guide on understanding how best to go about your home’s gas plumbing needs.

First things first: before beginning any kind of work with gas pipes, make sure that you take the necessary precautions. This means using the right equipment and protective gear so as not to endanger yourself or others around you. Make sure there are no open flames near the area where the work is being done, and be aware of any possible leaks in the system while working. Taking these steps will ensure that everything runs smoothly and safely when dealing with gas lines.

Now let’s move on to discussing the types of materials used for gas piping systems. When preparing your project, consider what type of material would be most appropriate for both longevity and affordability.

Steel pipe is usually preferred due to its high-quality construction and durability over time; however, plastic pipework can also provide an ideal solution depending on the installation requirements. Research into local building codes should reveal which option may be more suitable for your particular situation.

Let’s explore further now how each material performs…

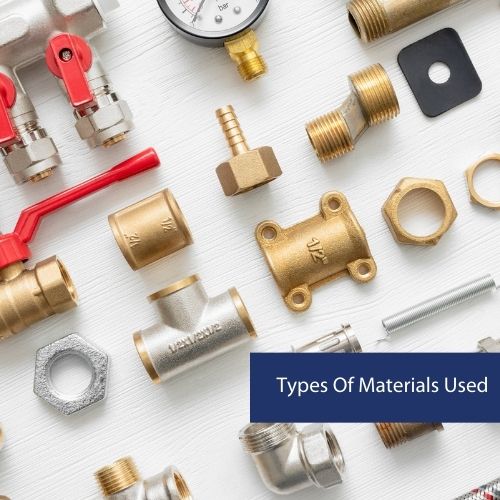

Types Of Materials Used

Did you know that the natural gas plumbing industry is estimated to be worth $13 billion in 2020? That means it’s a huge business, and there are lots of materials involved.

When it comes to materials for natural gas plumbing projects, quality matters above all else. Plumbers must always use high-grade pipes, valves, fittings, and other components when working with gas lines. The wrong kind of material can cause serious safety issues or even lead to an explosion.

Stainless steel piping is often used for interior runs because it won’t corrode over time. For exterior runs, copper tubing may be preferable due to its durability in harsh weather conditions. Fittings should also be made from durable brass or bronze alloy—anything lower grade could start leaking after some time has passed.

Knowing which type of material works best for each situation will help ensure your installation goes smoothly while keeping everyone safe. With this knowledge under their belt, plumbers can move on to learning about useful installation tips…

Installation Tips

Now that you have the materials and tools needed for a successful installation, it’s time to get started. When installing gas plumbing there are several tips and tricks to keep in mind.

Start with making sure all your measurements are precise; this will ensure everything fits together properly. It’s also important to check for leaks after every fitting is secured so you can avoid any potential hazards down the line.

Another pro tip is to use thread seal tape or paste when connecting threaded pipes – this helps create an airtight connection. Additionally, make sure that fittings like elbows and tees are connected firmly, as they’re responsible for directing the flow of gas safely around corners. If these pieces aren’t installed correctly, then not only could you be dealing with faulty connections but potentially hazardous ones too!

With safety being paramount, following these steps can help prevent trouble further down the road. Now let’s move on to troubleshooting common issues…

Troubleshooting Common Issues

It’s like trying to fix a leaky pipe – it can feel like you’re chasing your tail.

Troubleshooting common issues with gas plumbing is no different, but with the right tools and knowledge in hand, any problem can be solved.

Take some time to do your research; this will help save time in the long run.

Get yourself familiarized with all of the components involved so that when something goes wrong, you have an idea of where to look first.

Make sure to measure twice and cut once; double-check everything before committing to a repair or installation job.

Taking extra care now could mean having fewer headaches down the line!

With practice and patience on your side, you’ll soon get into a groove for troubleshooting common gas plumbing issues – just remember to stay safety conscious at all times and exercise caution around combustible materials.

Best Practices For Maintenance

Now that you’ve got a good handle on troubleshooting common gas plumbing issues, let’s move on to best practices for maintenance. Proper maintenance is the key to keeping your system running smoothly and problem-free.

Here are four easy steps to help you get started:

- Test – Regularly check for any leaks or weak spots in pipes, valves, seals, and connections. Ensure all fittings are secure as well.

- Inspect – Keep an eye out for corrosion or rust buildup which can weaken pipe walls and cause piping to fail over time.

- Clean – Periodically flush out faucets, drains, traps, and other components with clean water to remove built-up residue from sediment accumulation and mineral deposits.

- Preventative Maintenance – Replace worn parts regularly before they become a hazard or lead to expensive repairs down the road.

These simple tasks don’t require too much of your time but can save you lots of money in the long run! As experienced plumbers know, prevention is better than cure—so take some extra care while maintaining your gas plumbing systems to ensure optimal performance and longevity of equipment life span.

Additionally, if you find yourself needing more guidance or advice when it comes to properly maintaining your gas plumbing system, be sure to contact a qualified professional right away who will be able to assist you further with their expertise and knowledge regarding safety regulations and code requirements associated with these types of installations. You should never attempt any sort of repair work yourself unless instructed by a licensed contractor as this could potentially put both people involved at risk due to poor handling/installation techniques being used during the process.

Conclusion

As a plumber, I’ve seen how understanding gas plumbing can help make your life easier. With the right knowledge and safety precautions in place, you’re sure to have a successful installation or repair job.

When it comes to materials, it’s important that you use quality parts for all of your projects. This will ensure that everything is set up correctly and safely the first time around.

Additionally, having an idea of common issues before they happen will save you time and money down the line.

Finally, regular maintenance is key when dealing with any type of gas system. By taking precautionary steps like checking connections regularly and replacing worn-out components promptly, you’ll be able to keep your system running smoothly without costly repairs later on.

With these tips in mind, you should now feel more comfortable tackling any gas plumbing project!