What Is Plumbing?

This article provides a comprehensive overview of plumbing, exploring its fundamental concepts, materials, and tools, as well as the intricacies of installation and maintenance. It covers the different types of plumbing systems, the roles of various components, and the impact of plumbing on health and safety. Additionally, the article discusses the regulatory framework governing plumbing practices, with a focus on both national standards and specific regulations in the state of Oklahoma. Readers will gain insight into the licensing requirements for plumbers, the steps to obtain and maintain a plumbing license, and the importance of continuing education in the plumbing profession. This detailed guide is designed to equip readers with essential knowledge about plumbing systems and the professional standards that ensure their safe and efficient operation.

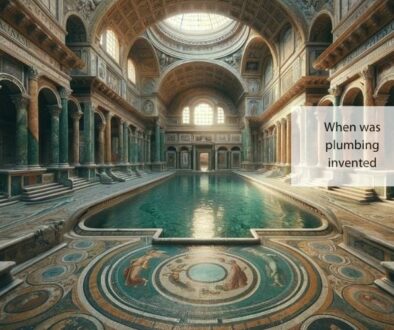

What is the History of Plumbing?

The history of plumbing dates back to ancient civilizations, where early plumbing systems were developed to provide clean water and remove waste. The earliest known plumbing systems were found in Ancient Egypt around 2500 BCE, where copper pipes were used to build sophisticated water systems for irrigation and bathing. The ancient Greeks and Romans advanced plumbing technology significantly, with the Romans constructing extensive aqueduct systems to transport water over long distances and developing public baths, fountains, and sophisticated sewer systems like the Cloaca Maxima. During the Middle Ages, plumbing technology stagnated, but it saw a resurgence during the Renaissance with the introduction of cast iron pipes and more advanced sewage disposal systems. The 19th century brought further advancements, including the development of modern indoor plumbing, sanitary sewers, and water treatment facilities, significantly improving public health. Today, plumbing systems are highly advanced, incorporating a wide range of materials and technologies to ensure safe, efficient, and reliable water supply and waste management.

What are the Basic Concepts of Plumbing?

Plumbing involves the system of pipes, fixtures, and other apparatus required for the water supply, heating, and sanitation in a building. It encompasses a wide range of tasks, including the installation of pipes, valves, fixtures, and fittings, as well as the repair and maintenance of these systems. At its core, plumbing focuses on ensuring the safe and efficient delivery of water for various uses and the proper disposal of wastewater. Key concepts include water supply, drainage, venting, and understanding the materials used, such as copper, PVC, and PEX pipes. Additionally, plumbing involves adhering to building codes and regulations to ensure safety and functionality.

What is the definition of plumbing?

Plumbing is defined as the system of pipes, fixtures, and other apparatus required to bring water into buildings and remove wastewater. It includes the installation, repair, and maintenance of these systems to ensure the proper functioning of water supply and sanitation. Plumbing covers a broad range of components, such as water heaters, faucets, sinks, toilets, and showers, as well as the complex network of pipes that connect these elements. This essential service ensures that clean water is available for drinking, cooking, and cleaning, and that waste is effectively removed to maintain a hygienic environment.

What are the main components of a plumbing system?

Main Components of a Plumbing System:

- Pipes and Tubes:

- Used for transporting water and waste.

- Common materials include copper, PVC, and PEX.

- Fittings and Valves:

- Connect and control the flow within the piping system.

- Includes elbows, tees, couplings, and shut-off valves.

- Fixtures:

- End-use points for water, such as sinks, toilets, showers, and bathtubs.

- Also includes faucets and spigots.

- Drainage System:

- Removes wastewater from fixtures and directs it to the sewer or septic system.

- Includes traps, vents, and drain pipes.

- Water Supply System:

- Delivers potable water to fixtures.

- Includes main supply lines, distribution pipes, and pressure regulators.

- Water Heater:

- Heats water for domestic use.

- Types include tankless, tank, and solar water heaters.

- Venting System:

- Allows air to enter the drainage system to maintain proper pressure and flow.

- Prevents the siphoning of water from traps.

What are the functions of pipes and fittings?

Pipes and fittings are fundamental components of any plumbing system, serving critical roles in water delivery and waste removal. Pipes transport water from the main supply to various fixtures such as sinks, showers, and toilets, as well as carry wastewater away to the sewer or septic system. They must be durable, leak-proof, and capable of withstanding pressure variations. Fittings, which include elbows, tees, couplings, and valves, connect sections of pipe, change the direction of water flow, and regulate the flow and pressure within the system. Together, pipes and fittings ensure a continuous and controlled flow of water, maintaining the efficiency and reliability of the plumbing infrastructure.

What role do valves play in plumbing?

Valves are crucial in plumbing systems, as they control the flow and pressure of water throughout the pipes. They allow for the regulation and isolation of different sections of the plumbing network, making it possible to perform repairs and maintenance without shutting off the entire system. Common types of valves include gate valves, ball valves, globe valves, and check valves, each serving specific functions. Gate and ball valves are primarily used for on/off control, providing a tight seal when closed. Globe valves are used for regulating flow, while check valves prevent backflow, ensuring that water flows in only one direction. By managing water flow and pressure, valves help maintain the safety, efficiency, and functionality of the plumbing system.

How do fixtures and appliances integrate into the system?

Fixtures and appliances are integral to plumbing systems, providing end-use points for water and waste management. Fixtures such as sinks, toilets, showers, and bathtubs are directly connected to both the water supply and drainage systems, allowing for the convenient use and disposal of water. Appliances like dishwashers, washing machines, and water heaters also connect to these systems, requiring proper installation to ensure efficient operation. The integration process involves connecting these fixtures and appliances to the main water supply lines and drainage pipes using appropriate fittings and ensuring all connections are sealed to prevent leaks.

How does plumbing work in residential buildings?

In residential buildings, plumbing systems are designed to provide a reliable supply of clean water and an efficient means of waste removal. The system starts with the main water line, which connects the home to the municipal water supply or a private well. From there, water is distributed through a network of pipes to various fixtures and appliances, such as sinks, toilets, showers, and water heaters. Each fixture is equipped with shut-off valves for individual control. Wastewater from these fixtures flows into drain pipes and is directed to the home’s main sewer line or septic tank. Vent pipes are installed to release sewer gases and maintain proper pressure in the drainage system, preventing the siphoning of water from traps. Regular maintenance and prompt repairs are essential to ensure the system operates smoothly and to prevent leaks, clogs, and other issues that can disrupt household activities.

How is water supplied to a residential building?

Water supply to a residential building begins with a connection to the municipal water main or a private well. The main water line enters the home, usually through a water meter that measures usage. From there, the water passes through a pressure regulator to ensure consistent pressure. The main supply line then branches off into a network of smaller pipes that deliver water to various fixtures and appliances. Cold water pipes distribute unheated water directly, while hot water pipes route water through a water heater before reaching fixtures. Each branch typically has shut-off valves for maintenance and repair purposes. The plumbing system also includes backflow prevention devices to protect the potable water supply from contamination. This integrated network ensures that residents have access to clean, pressurized water for drinking, cooking, cleaning, and other daily activities.

What are the common residential drainage systems?

- Gravity-Fed Drainage System:

- Relies on gravity to move wastewater from fixtures to the main sewer line or septic tank.

- Includes a network of drain pipes, traps, and vents.

- Septic System:

- Used in areas without access to municipal sewer systems.

- Consists of a septic tank and a drain field where wastewater is treated and absorbed into the ground.

- Municipal Sewer Connection:

- Connects the home’s drainage system to the municipal sewer system.

- Wastewater is transported to a central treatment facility for processing.

- French Drains:

- Used for outdoor drainage to prevent water accumulation around the foundation.

- Consists of a trench filled with gravel and a perforated pipe that redirects water away from the house.

- Sump Pump System:

- Installed in basements or crawl spaces to remove accumulated water.

- Consists of a sump pit and a pump that discharges water to an exterior drainage area.

- Backwater Valve:

- Prevents sewage from backing up into the home during heavy rainfall or sewer blockages.

- Installed in the main sewer line.

How does a hot water system operate in homes?

A hot water system in homes operates by heating water and distributing it to various fixtures and appliances that require hot water. The process typically begins with a water heater, which can be tank-based, tankless, or solar-powered. In a tank-based system, cold water enters the tank and is heated by gas or electric elements. The heated water is stored in the tank until needed. In a tankless system, water is heated on-demand as it flows through a heat exchanger. Solar-powered systems use solar collectors to heat water, which is then stored in a tank or used directly. Once heated, the hot water is distributed through a network of pipes to faucets, showers, dishwashers, and washing machines. Temperature and pressure are regulated by a thermostat and pressure relief valves to ensure safety and comfort. Proper insulation of pipes and the water heater is essential to maintain efficiency and prevent heat loss. Regular maintenance, such as flushing the tank and checking for leaks, ensures the longevity and reliability of the hot water system.

What are the different types of plumbing systems?

The different types of plumbing systems are:

- Potable Water Supply System:

- Delivers clean, safe drinking water to fixtures.

- Includes a network of pipes, valves, and faucets.

- Sanitary Drainage System:

- Removes wastewater from fixtures and directs it to the sewer or septic system.

- Comprises drain pipes, traps, and vent pipes.

- Stormwater Drainage System:

- Manages rainwater runoff from roofs, driveways, and other surfaces.

- Consists of gutters, downspouts, and drainage pipes.

- Gas Plumbing System:

- Distributes natural gas or propane to appliances such as stoves, water heaters, and furnaces.

- Includes gas pipes, regulators, and shut-off valves.

- Irrigation System:

- Provides water for landscaping and gardening.

- Includes sprinkler heads, drip lines, and control valves.

- Hydronic Heating System:

- Uses water to transfer heat from boilers to radiators or underfloor heating systems.

- Comprises a closed loop of pipes, pumps, and heat exchangers.

- Greywater Recycling System:

- Collects and treats greywater from sinks, showers, and laundry for reuse in irrigation or toilet flushing.

- Includes storage tanks, filters, and distribution pipes.

How do potable water systems differ from wastewater systems?

Potable water systems and wastewater systems serve distinct functions within a plumbing network. Potable water systems are designed to deliver clean, safe drinking water to various fixtures such as sinks, showers, and appliances. This system starts at the municipal water supply or a private well, where water is treated and then distributed through a network of pipes. The water is maintained under pressure to ensure it reaches all points of use efficiently. On the other hand, wastewater systems focus on removing and treating used water from fixtures. This system includes drain pipes, traps, and vent pipes that guide wastewater away from the home to either a municipal sewer system or a private septic tank. Wastewater systems rely on gravity for drainage and incorporate venting to prevent sewer gases from entering the home. The key difference lies in their purpose: potable water systems ensure the delivery of clean water, while wastewater systems ensure the safe removal and treatment of used water.

What are the characteristics of a stormwater drainage system?

A stormwater drainage system is designed to manage rainwater runoff and prevent flooding in residential and commercial areas. Its primary components include gutters, downspouts, catch basins, storm drains, and underground piping. Gutters and downspouts collect rainwater from roofs and direct it away from the building’s foundation. Catch basins and storm drains capture runoff from streets, driveways, and other surfaces, channeling the water into underground pipes. These pipes then convey the water to retention ponds, natural water bodies, or municipal stormwater systems. Key characteristics of an effective stormwater drainage system include proper grading to direct water flow, adequate capacity to handle heavy rainfall, and regular maintenance to prevent blockages. Additionally, modern systems often incorporate features like permeable pavements and rain gardens to enhance water absorption and reduce runoff, promoting sustainable water management practices.

How are plumbing systems categorized in commercial buildings?

Categorization of Plumbing Systems in Commercial Buildings:

- Domestic Water System:

- Provides potable water for drinking, cooking, and sanitation.

- Includes a network of pipes, pumps, and storage tanks.

- Sanitary Drainage System:

- Removes wastewater from restrooms, kitchens, and other areas.

- Comprises drain pipes, traps, and vent pipes connected to the municipal sewer or a private septic system.

- Stormwater Drainage System:

- Manages rainwater runoff from roofs, parking lots, and other surfaces.

- Utilizes gutters, downspouts, catch basins, and underground piping.

- Fire Suppression System:

- Provides water for fire sprinkler systems and standpipes.

- Includes dedicated water mains, pumps, and sprinkler heads.

- HVAC Condensate System:

- Removes condensate produced by heating, ventilation, and air conditioning systems.

- Consists of condensate drain lines and pumps.

- Gas Plumbing System:

- Distributes natural gas or propane to heating systems, water heaters, and commercial kitchen appliances.

- Includes gas pipes, regulators, and shut-off valves.

- Irrigation System:

- Supplies water for landscaping and green areas around the building.

- Incorporates sprinkler heads, drip lines, and control valves.

- Specialty Water Systems:

- Provides water for specific uses such as laboratory equipment, medical facilities, or industrial processes.

- Custom-designed to meet unique requirements.

What are the Common Plumbing Materials and Tools?

Pipes

- Copper: Durable and corrosion-resistant, used for both hot and cold water supply lines.

- PVC (Polyvinyl Chloride): Lightweight and easy to install, used for drain, waste, and vent systems.

- PEX (Cross-Linked Polyethylene): Flexible and easy to install, used for water supply lines.

- CPVC (Chlorinated Polyvinyl Chloride): Resistant to heat and chemicals, used for hot and cold water supply.

- Galvanized Steel: Durable but prone to corrosion, used in older homes for water supply lines.

Fittings

- Elbows, Tees, and Couplings: Used to connect pipes and change directions.

- Adapters and Reducers: Used to join different types or sizes of pipes.

- Caps and Plugs: Used to seal the ends of pipes.

Valves:

- Ball Valves: Provide reliable shut-off and control of water flow.

- Gate Valves: Used to completely stop the flow of water.

- Check Valves: Prevent backflow in the system.

Fixtures:

- Faucets, Sinks, and Toilets: Common fixtures in bathrooms and kitchens.

- Showers and Bathtubs: Provide bathing facilities.

- Sealants and Adhesives:

- Teflon Tape: Used to seal threaded pipe joints.

- Pipe Dope: A sealant paste used on pipe threads.

- PVC Cement: Used to join PVC pipes and fittings.

Common Plumbing Tools:

- Pipe Wrenches:

- Used for gripping and turning pipes.

- Plunger:

- Used to clear clogs in toilets and drains.

- Pipe Cutters:

- Used to cut pipes to the desired length.

- Adjustable Wrenches:

- Versatile tool used for tightening and loosening nuts and bolts.

- Plumber’s Tape (Thread Seal Tape):

- Used to create a watertight seal on threaded pipe connections.

- Pipe Bender:

- Used to bend pipes without kinking them.

- Plumber’s Torch:

- Used for soldering copper pipes and fittings.

- Auger (Plumber’s Snake):

- Used to clear blockages in pipes and drains.

- Pliers:

- Used for gripping, twisting, and cutting.

- Hacksaw:

- Used to cut metal and plastic pipes.

What materials are commonly used in plumbing?

Plumbing systems rely on various materials, each chosen for its specific properties and applications. Copper is a popular choice for water supply lines due to its durability and corrosion resistance. PVC (Polyvinyl Chloride) is widely used for drain, waste, and vent systems because it is lightweight, easy to install, and resistant to chemicals. PEX (Cross-Linked Polyethylene) is favored for its flexibility and ease of installation in water supply lines. CPVC (Chlorinated Polyvinyl Chloride) offers similar benefits to PVC but can withstand higher temperatures, making it suitable for both hot and cold water supply. Galvanized steel pipes, though prone to corrosion, are still found in older homes. Brass and stainless steel are used for fittings and fixtures due to their strength and resistance to corrosion.

What are the essential tools for plumbing?

Plumbing requires a range of specialized tools to ensure proper installation, maintenance, and repair of systems. Pipe wrenches are fundamental for gripping and turning pipes, while adjustable wrenches are versatile for tightening and loosening nuts and bolts. Plungers are indispensable for clearing clogs in toilets and drains. Pipe cutters, available in different types for various materials, are used to cut pipes to the desired length. Plumber’s tape (thread seal tape) is crucial for creating watertight seals on threaded connections. Pipe benders allow for bending pipes without kinking them, and plumber’s torches are used for soldering copper pipes and fittings. Augers, or plumber’s snakes, are essential for clearing blockages in pipes and drains. Pliers, including slip-joint and locking pliers, are used for gripping, twisting, and cutting. Hacksaws are useful for cutting metal and plastic pipes. These tools, along with others like basin wrenches and faucet seat wrenches, equip plumbers to handle a wide range of plumbing tasks efficiently.

How do different materials affect plumbing performance?

Different materials significantly impact the performance, durability, and efficiency of plumbing systems. Copper pipes are known for their long lifespan, reliability, and resistance to corrosion, making them ideal for water supply lines. PVC (Polyvinyl Chloride) pipes are lightweight, easy to install, and resistant to chemicals, making them suitable for drain, waste, and vent systems. PEX (Cross-Linked Polyethylene) pipes offer flexibility and ease of installation, reducing labor costs and the need for fittings in water supply lines. CPVC (Chlorinated Polyvinyl Chloride) can handle higher temperatures and is suitable for both hot and cold water applications. However, each material has its limitations; for example, galvanized steel pipes, though durable, are prone to corrosion over time, which can lead to leaks and reduced water quality. The choice of material affects the system’s longevity, maintenance needs, and overall performance in delivering clean water and efficiently removing waste.

What are the benefits of using copper pipes?

Copper pipes offer numerous benefits that make them a popular choice in plumbing systems. Their durability and long lifespan mean that once installed, they can last for decades without needing replacement. Copper is highly resistant to corrosion and can withstand high temperatures, making it suitable for both hot and cold water lines. Its biostatic properties inhibit the growth of harmful bacteria, contributing to safer drinking water. Copper pipes are also recyclable, which is an environmental advantage. Additionally, copper’s strength allows it to withstand high water pressure, reducing the risk of leaks and bursts. These qualities make copper pipes a reliable and safe option for residential and commercial plumbing systems.

What are the disadvantages of using PVC pipes?

While PVC (Polyvinyl Chloride) pipes offer several advantages, such as being lightweight, easy to install, and resistant to chemicals, they also have certain disadvantages. One major drawback is their susceptibility to UV light; prolonged exposure can degrade the material, making it brittle and prone to cracking. PVC pipes are also less suitable for hot water applications as they can deform under high temperatures. Additionally, they may not be as durable as metal pipes in certain situations, potentially leading to breaks or leaks under high pressure or impact. Another concern is that PVC can release harmful chemicals when burned, posing environmental and health risks. These disadvantages limit the use of PVC pipes to specific applications, primarily in cold water and waste management systems.

What are the Regulations Governing Plumbing?

Regulations governing plumbing are established to ensure the safety, reliability, and efficiency of plumbing systems. These regulations are enforced by local, state, and federal authorities and are typically detailed in building codes. They cover various aspects of plumbing work, including the installation, maintenance, and repair of water supply and drainage systems. Regulations specify the types of materials that can be used, ensuring they are safe and durable. They also mandate proper installation techniques to prevent leaks, contamination, and other issues. Additionally, plumbing regulations require the use of backflow prevention devices, adequate venting, and proper drainage to protect public health. Plumbers must obtain necessary permits and inspections to ensure compliance with these regulations, which are designed to prevent plumbing failures and protect the health and safety of the public.

What are the national plumbing codes and standards?

National plumbing codes and standards provide a framework for the design, installation, and maintenance of plumbing systems, ensuring consistency and safety across the industry. The two primary codes in the United States are the International Plumbing Code (IPC) and the Uniform Plumbing Code (UPC). The IPC, developed by the International Code Council (ICC), focuses on providing comprehensive regulations for plumbing system design, installation, and inspection. The UPC, created by the International Association of Plumbing and Mechanical Officials (IAPMO), emphasizes safe and efficient plumbing systems through uniform standards. Both codes cover critical aspects such as materials, pipe sizing, water supply, drainage, venting, and fixture installation. They also include provisions for backflow prevention, water conservation, and energy efficiency. Adherence to these codes is mandatory, and plumbers must stay updated on any revisions to ensure their work complies with current standards. Compliance with national plumbing codes helps ensure public health and safety by preventing plumbing failures and ensuring the proper functioning of plumbing systems.

How does the International Plumbing Code (IPC) impact plumbing practices?

The International Plumbing Code (IPC) significantly impacts plumbing practices by providing a comprehensive set of regulations that standardize plumbing system design, installation, and maintenance. Developed by the International Code Council (ICC), the IPC ensures that plumbing systems are safe, efficient, and reliable. It covers all aspects of plumbing, including water supply, drainage, venting, and fixture installation, and mandates the use of approved materials and methods to prevent leaks, contamination, and other issues. The IPC also includes provisions for backflow prevention, ensuring that potable water remains uncontaminated. By establishing uniform standards, the IPC helps prevent plumbing failures and ensures that systems are designed to handle expected loads and pressures. Compliance with the IPC is mandatory in many jurisdictions, and plumbers must stay updated on the latest code revisions to ensure their work meets current standards. This code not only protects public health and safety but also promotes sustainability through water conservation and energy efficiency measures. Adhering to the IPC ensures that plumbing practices are consistent, reliable, and aligned with modern safety and environmental standards.

What are the key provisions of the Uniform Plumbing Code (UPC)?

The Uniform Plumbing Code (UPC) includes key provisions designed to ensure the safety, efficiency, and reliability of plumbing systems. Developed by the International Association of Plumbing and Mechanical Officials (IAPMO), the UPC sets uniform standards for the installation, inspection, and maintenance of plumbing systems. Key provisions include detailed guidelines on the proper sizing and installation of pipes, ensuring adequate water pressure and flow. The code mandates the use of approved materials, such as lead-free pipes and fittings, to prevent contamination and ensure durability. The UPC also emphasizes backflow prevention to protect potable water supplies from contamination. It includes requirements for proper venting to allow the safe and efficient removal of sewer gases and prevent trap siphoning. Drainage system design is also covered, with specifications for pipe slopes and cleanouts to ensure effective waste removal. The UPC promotes water conservation through regulations on fixture flow rates and the use of efficient water heating systems. Compliance with the UPC is essential for plumbers to ensure their work meets safety standards, protects public health, and aligns with modern environmental practices.

How do local regulations affect plumbing installations?

Local regulations significantly impact plumbing installations by ensuring that all work meets specific safety, health, and environmental standards tailored to the area’s unique needs. These regulations, often based on national codes such as the IPC and UPC, can include additional requirements to address local concerns, such as water conservation measures in drought-prone regions or seismic safety measures in earthquake-prone areas. Plumbers must adhere to these local codes, which dictate the types of materials that can be used, the methods of installation, and the necessary specifications for various plumbing components. Compliance with local regulations ensures that plumbing systems are safe, efficient, and environmentally responsible, preventing issues such as water contamination, leaks, and structural damage. Failure to comply with these regulations can result in fines, delays in project completion, and potential health hazards.

What are the common local plumbing permits required?

Common local plumbing permits are essential for ensuring that plumbing installations and modifications comply with building codes and safety standards. Typically, permits are required for major plumbing projects, such as installing or replacing water heaters, sewer lines, and water supply pipes. Remodeling projects involving kitchens or bathrooms also necessitate permits, especially when relocating fixtures or altering the plumbing system. Additionally, permits may be required for the installation of irrigation systems, backflow prevention devices, and gas lines. Obtaining these permits involves submitting detailed plans and specifications to the local building authority, which reviews them for compliance with local regulations. Securing the necessary permits helps ensure that plumbing work is performed to standard, safeguarding public health and safety.

How do local inspections ensure plumbing compliance?

Local inspections play a crucial role in ensuring plumbing compliance by verifying that installations and repairs adhere to relevant codes and regulations. After obtaining the necessary permits, a licensed inspector will review the plumbing work at various stages of completion. Inspections typically include checking the installation of pipes, fittings, and fixtures, ensuring proper venting and drainage, and verifying the integrity of water supply systems. The inspector will also ensure that backflow prevention measures are in place and that all materials used meet local standards. Any deficiencies or code violations identified during the inspection must be corrected before the project can proceed or be finalized. These inspections are critical for maintaining the safety, functionality, and longevity of plumbing systems, preventing issues such as leaks, contamination, and structural damage.

What are the licensing requirements for plumbers?

Licensing requirements for plumbers vary by location but generally include a combination of education, practical experience, and passing standardized exams. Most regions require aspiring plumbers to complete a high school diploma or equivalent, followed by enrollment in a plumbing apprenticeship program. These programs, which can last four to five years, combine classroom instruction with hands-on training under the supervision of experienced plumbers. Upon completing the apprenticeship, candidates must pass a licensing exam that tests their knowledge of plumbing codes, safety regulations, and practical skills. Some areas also require a journeyman plumber to gain additional experience before applying for a master plumber license. Licensing ensures that plumbers possess the necessary skills and knowledge to perform their work safely and competently, protecting public health and safety.

What are the steps to become a licensed plumber?

The steps to become a licensed plumber typically begin with obtaining a high school diploma or equivalent, focusing on subjects like math and science. The next step is to complete a plumbing apprenticeship program, which involves both classroom education and on-the-job training over four to five years. Apprentices learn essential skills, including pipe installation, system design, and troubleshooting under the guidance of experienced plumbers. After completing the apprenticeship, candidates must pass a licensing exam that covers local plumbing codes, safety practices, and technical knowledge. Some regions may require additional work experience as a journeyman plumber before allowing candidates to apply for a master plumber license. Throughout this process, aspiring plumbers must adhere to local regulations and stay updated on any changes in plumbing standards and practices.

How do continuing education requirements affect plumbers?

Continuing education requirements for plumbers ensure that they stay updated with the latest advancements, technologies, and regulations in the plumbing industry. These requirements typically mandate that licensed plumbers complete a certain number of hours of additional training or coursework periodically, often every one to two years. Continuing education can cover a range of topics, including new plumbing codes, advanced installation techniques, safety practices, and the use of new materials and tools. By fulfilling these requirements, plumbers maintain their licenses and stay current with industry standards, which enhances their professional skills and knowledge. This ongoing education helps plumbers provide better service to their clients, adapt to changes in the industry, and ensure compliance with evolving safety and regulatory standards.

How is Plumbing Managed in the USA, Including the State of Oklahoma?

Plumbing in the USA is managed through a combination of federal, state, and local regulations designed to ensure safety, efficiency, and environmental protection. At the federal level, agencies like the Environmental Protection Agency (EPA) set standards for water quality and waste management. Each state, including Oklahoma, adopts and enforces its plumbing codes based on national standards such as the International Plumbing Code (IPC) or the Uniform Plumbing Code (UPC). Oklahoma, for example, follows the Oklahoma Plumbing License Law, which requires plumbers to be licensed and adhere to state-specific regulations. Local municipalities may also implement additional codes and inspection requirements to address regional concerns. This multi-tiered approach ensures that plumbing systems are designed, installed, and maintained to protect public health and the environment.

What are the general plumbing regulations in the USA?

General plumbing regulations in the USA are designed to ensure the safety, reliability, and efficiency of plumbing systems. These regulations are based on national codes like the International Plumbing Code (IPC) and the Uniform Plumbing Code (UPC), which provide comprehensive guidelines for all aspects of plumbing work. Regulations cover the installation of pipes, fixtures, and fittings, ensuring they meet specific standards for materials, sizing, and performance. They also mandate proper venting, backflow prevention, and adequate water pressure. Additionally, regulations require that all plumbing work be performed by licensed professionals who adhere to local building codes and standards. Regular inspections are mandated to ensure compliance and to address any issues that may arise, protecting both the public and the environment from potential hazards.

How do federal and state regulations differ?

Federal and state regulations in plumbing differ mainly in scope and specificity. Federal regulations, set by agencies like the Environmental Protection Agency (EPA), focus on broad issues such as water quality, lead content in plumbing materials, and waste management to protect public health and the environment. These regulations establish baseline standards that states must meet or exceed. State regulations, on the other hand, are more detailed and tailored to address local needs and conditions. Each state adopts its plumbing code, often based on national standards like the IPC or UPC, and may include additional requirements to address regional concerns such as water conservation in drought-prone areas or seismic safety in earthquake zones. States also oversee the licensing and certification of plumbers, ensuring they meet specific educational and professional criteria. This dual regulatory approach ensures comprehensive oversight of plumbing practices across the country.

What role does the Environmental Protection Agency (EPA) play in plumbing?

The Environmental Protection Agency (EPA) plays a critical role in plumbing by setting standards and regulations that protect water quality and promote environmental sustainability. The EPA enforces the Safe Drinking Water Act, which establishes criteria for the quality of drinking water supplied to the public. This includes setting limits on contaminants and requiring regular testing and reporting by water suppliers. The EPA also regulates the use of materials in plumbing systems to prevent lead and other harmful substances from leaching into the water supply. Additionally, the EPA promotes water conservation through initiatives like the WaterSense program, which certifies high-efficiency plumbing fixtures and appliances. By setting these standards and promoting best practices, the EPA helps ensure that plumbing systems across the country are safe, reliable, and environmentally friendly.

What are the specific plumbing regulations in the State of Oklahoma?

The State of Oklahoma follows specific plumbing regulations to ensure the safety, functionality, and compliance of plumbing systems within its jurisdiction. These regulations are based on the Oklahoma Plumbing License Law and the adopted version of the International Plumbing Code (IPC). Oklahoma requires all plumbing work to be performed by licensed professionals who have met the state’s educational and practical training requirements. The regulations cover various aspects of plumbing, including the installation, repair, and maintenance of water supply lines, drainage systems, and gas piping. Additionally, Oklahoma mandates the use of approved materials and methods to prevent leaks, contamination, and other issues. Regular inspections and adherence to local building codes are enforced to maintain high standards of public health and safety.

What are the key provisions of the Oklahoma Plumbing Code?

The Oklahoma Plumbing Code incorporates key provisions from the International Plumbing Code (IPC) and adds state-specific requirements to address local needs. Key provisions include detailed guidelines for the installation and sizing of pipes, ensuring adequate water pressure and flow. The code mandates the use of approved materials, such as lead-free pipes and fittings, to prevent contamination and ensure durability. It also requires proper venting to allow safe removal of sewer gases and prevent trap siphoning. The code includes backflow prevention measures to protect potable water supplies from contamination. Drainage system design specifications ensure effective waste removal, with required slopes and cleanouts. The code also promotes water conservation through regulations on fixture flow rates and efficient water heating systems. Compliance with these provisions ensures safe, reliable, and efficient plumbing systems throughout Oklahoma.

How does Oklahoma manage plumbing inspections and permits?

Oklahoma manages plumbing inspections and permits through a structured process overseen by local building authorities. Before starting any plumbing project, plumbers must obtain the necessary permits by submitting detailed plans and specifications that comply with the Oklahoma Plumbing Code. Once a permit is issued, inspections are conducted at various stages of the project to ensure compliance with code requirements. These inspections typically include checking the installation of pipes, fittings, and fixtures, verifying proper venting and drainage, and ensuring the integrity of the water supply system. Inspectors also ensure that backflow prevention measures are in place and that all materials used meet state standards. Any deficiencies or code violations identified during inspections must be corrected before the project can proceed or be finalized. This process helps maintain high standards of safety, functionality, and compliance in plumbing installations across the state.

What are the licensing requirements for plumbers in Oklahoma?

Licensing requirements for plumbers in Oklahoma are designed to ensure that professionals in the field possess the necessary skills and knowledge to perform their work safely and competently. To become a licensed plumber in Oklahoma, individuals must first complete a high school diploma or equivalent. Following this, they must enroll in a state-approved apprenticeship program, which includes both classroom instruction and on-the-job training under the supervision of a licensed plumber. This program typically lasts four to five years. After completing the apprenticeship, candidates must pass a licensing examination that tests their knowledge of plumbing codes, safety regulations, and practical skills. Additionally, Oklahoma requires plumbers to adhere to the state’s specific plumbing codes and regulations to maintain their license.

How to obtain a plumbing license in Oklahoma?

To obtain a plumbing license in Oklahoma, candidates must follow a structured process. The first step is to complete a high school diploma or equivalent. Next, candidates must enroll in and complete a state-approved plumbing apprenticeship program, which involves extensive hands-on training and classroom education over several years. Upon completing the apprenticeship, candidates must apply to take the Oklahoma plumbing licensing examination. This exam tests their understanding of state plumbing codes, safety practices, and technical skills. Once they pass the exam, candidates can apply for their journeyman plumber license. To advance further, journeyman plumbers can gain additional experience and eventually apply for a master plumber license, which allows them to take on more complex projects and supervise other plumbers.

What are the continuing education requirements for Oklahoma plumbers?

Continuing education requirements for Oklahoma plumbers are designed to ensure that professionals stay current with the latest developments in plumbing technology, codes, and practices. Licensed plumbers in Oklahoma must complete a specified number of continuing education hours during each licensing period, typically every three years. These courses cover various topics, including updates to plumbing codes, advanced installation techniques, safety protocols, and new materials and technologies. The Oklahoma Construction Industries Board (CIB) oversees these requirements and approves courses that meet the state’s standards. By fulfilling these continuing education requirements, plumbers ensure they maintain their licenses, enhance their professional skills, and stay informed about industry changes, ultimately providing better service to their clients.

What are the Health and Safety Considerations in Plumbing?

Health and safety considerations in plumbing are paramount to ensure the well-being of occupants and workers. Proper installation and maintenance are crucial to prevent leaks, water contamination, and structural damage. Plumbers must adhere to building codes and standards to ensure systems are safe and reliable. Using appropriate materials that are lead-free and resistant to corrosion helps maintain water quality. Regular inspections and timely repairs prevent issues such as mold growth, which can cause respiratory problems. Safe handling of tools and materials, as well as wearing protective gear, reduces the risk of injury for plumbers. Additionally, backflow prevention devices are essential to prevent contaminated water from entering the potable water supply. Implementing these measures ensures a safe and healthy environment for everyone.

How can plumbing systems impact health?

Plumbing systems have a significant impact on health, primarily through the provision of clean water and the safe removal of waste. Properly maintained plumbing ensures that drinking water is free from contaminants, reducing the risk of waterborne diseases. However, poorly maintained or faulty plumbing can lead to serious health issues. For example, leaks can result in mold growth, which can cause respiratory problems and allergic reactions. Contaminated water from corroded pipes or cross-connections can lead to gastrointestinal illnesses. Additionally, inadequate drainage systems can cause sewage backups, posing severe health risks. Ensuring plumbing systems are well-designed, properly installed, and regularly maintained is crucial for preventing these health hazards and promoting overall well-being.

What are the safety precautions for plumbers?

Plumbers must adhere to several safety precautions to minimize risks and ensure a safe working environment. Personal protective equipment (PPE), such as gloves, safety glasses, and steel-toed boots, is essential to protect against injuries from tools, chemicals, and sharp objects. Plumbers should also use ear protection in noisy environments and respirators when dealing with hazardous fumes. Proper handling and storage of tools and materials prevent accidents and injuries. It’s crucial to follow lockout/tagout procedures to ensure systems are de-energized before starting repairs. Plumbers should also be trained in first aid and emergency response. Ensuring good ventilation in confined spaces and being aware of potential hazards like asbestos, lead, and mold are also important. Regular safety training and adherence to OSHA (Occupational Safety and Health Administration) guidelines help maintain a safe work environment.